Common Pump Mistakes

Common Installation & Operation Mistakes in Pumps: Technical Causes and Solutions

Introduction

Pumps are fundamental in many industries—from water treatment and agriculture to oil, gas, and chemical processing. However, many instances of pump failure or reduced efficiency stem not from design flaws, but from installation and operational errors.

This article outlines the most common mistakes, their technical causes, and practical, standards-based solutions that align with global references such as ISO 9906 and ANSI/HI.

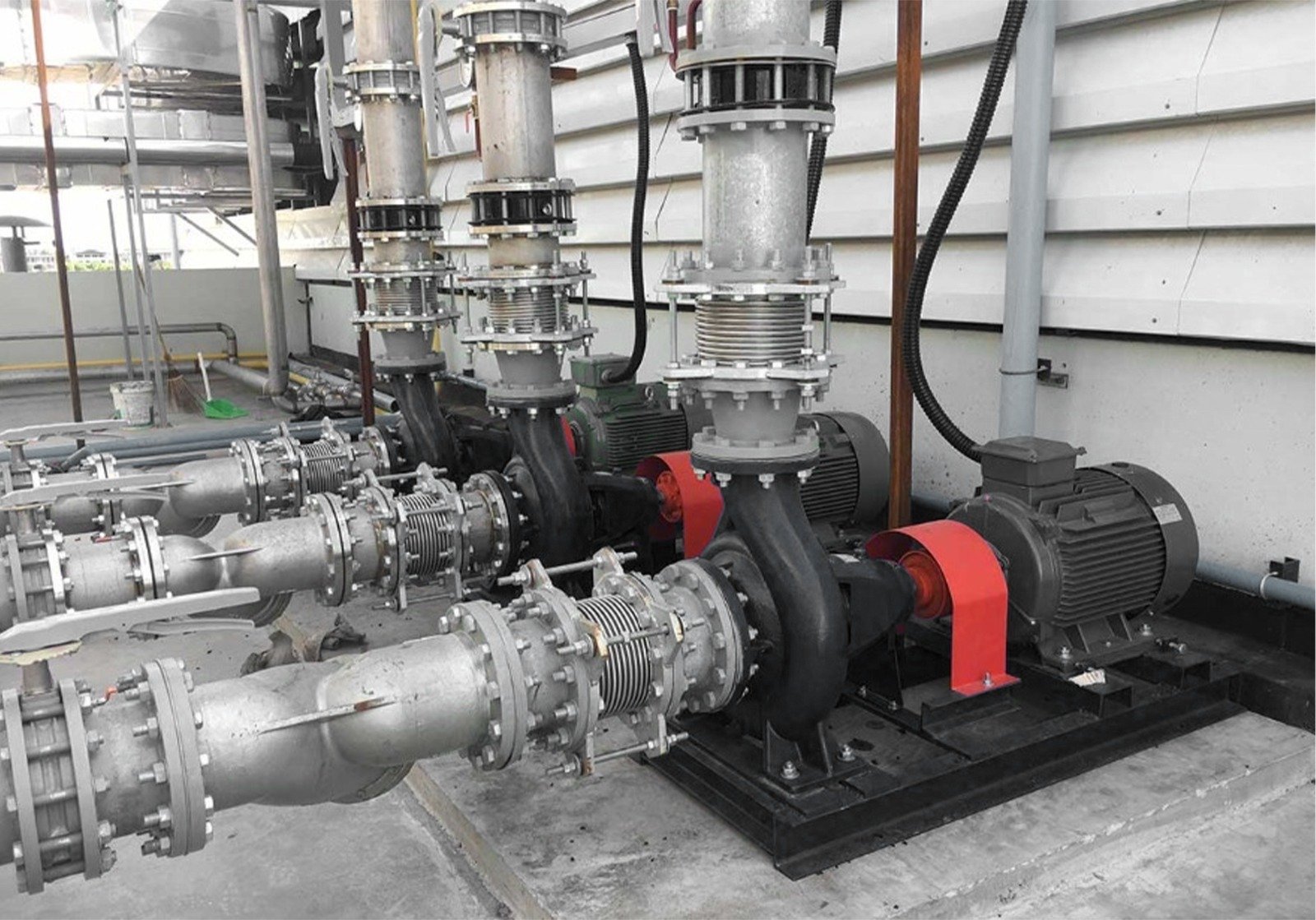

1. Shaft Misalignment

Description:

Occurs when the motor and pump shafts are not properly aligned, either horizontally or vertically.

Impact:

– Excessive vibration

– Seal and bearing damage

– Increased energy consumption

– Significantly reduced pump life

Solutions:

– Use precision laser alignment tools

– Ensure the baseplate is level and secure

– Recheck alignment after initial start-up or maintenance

2. Cavitation

Description:

When the pressure at the pump inlet falls below the vapor pressure of the liquid, vapor bubbles form and collapse violently inside the pump.

Impact:

– Severe impeller erosion

– Loud rattling or banging sounds

– Major drop in efficiency

Solutions:

– Ensure NPSHa > NPSHr

– Minimize suction line length and avoid sharp bends

– Prevent operation at high temperatures unless NPSH is properly accounted for

3. Dry Running

Description:

Operating the pump without liquid inside, commonly seen with self-priming or submersible pumps.

Impact:

– Seal burnout

– Shaft damage

– Complete pump failure within minutes

Solutions:

– Install level sensors or float switches

– Use dry-run protection systems

– Train staff on safe start-up procedures

4. Wrong Pump Selection for the Application

Description:

Using a pump not designed for the liquid’s characteristics (viscosity, temperature, solids content).

Impact:

– Frequent clogging

– Premature internal wear

– Low efficiency and high energy consumption

Solutions:

– Refer to hydraulic selection curves

– Match the pump specs to fluid properties

– Consult technical experts early in the design process

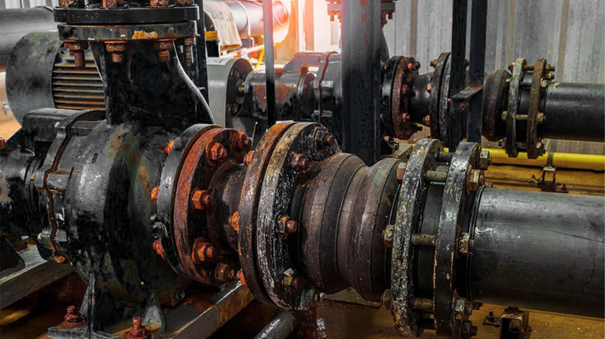

5. Improper Piping Installation

Description:

Incorrect support or alignment of suction/discharge piping, often leading to stress on the pump casing.

Impact:

– Pipe strain causing casing damage

– Seal and connection leaks

– Baseplate deformation

Solutions:

– Use independent pipe supports (not the pump body)

– Isolate pump vibration with proper mounts

– Install expansion joints if thermal changes are expected

6. Ignoring Operation & Maintenance Guidelines

Description:

Failure to follow OEM installation or maintenance instructions.

Impact:

– Undetected wear and tear

– Voiding of product warranty

– Catastrophic failure due to overlooked issues

Solutions:

– Provide visual guides near each pump

– Train operators regularly

– Use maintenance reminder apps or CMMS platforms

How These Mistakes Impact Pump Life

| Mistake | Expected Pump Life After Mistake | Normal Pump Life |

| Shaft misalignment | ~30% | 100% |

| Cavitation | ~50% | 100% |

| Dry running | Sometimes less than 5% | 100% |

| Wrong pump type for application | Varies based on severity | 100% |

Misalignment between pump and motor shafts, showing angular and parallel deviation

Cutaway Section Diagram:

Impeller erosion caused by cavitation—highlighted with damaged blade tips and bubble collapse zone

🖼️ Proposed Illustrations for Web or Print Use

1. 3D Visual:

Misalignment between pump and motor shafts, showing angular and parallel deviation.

2. Cutaway Section Diagram:

Impeller erosion caused by cavitation—highlighted with damaged blade tips and bubble collapse zones.

3. Graph:

A clear graph comparing NPSHa vs. NPSHr, showing the safe operating margin.

4. Infographic:

Side-by-side illustration of proper vs. improper piping support and alignment.

Conclusion

Avoiding these pump-related issues doesn’t require expensive technology—it requires technical awareness, adherence to standards, and proactive maintenance. At Niagara Pumps, we offer comprehensive solutions and support that help you maximize system reliability, energy efficiency, and long-term value.