How Choosing Long-Life Pumps

A Comprehensive Guide for Reliability and Efficiency:

Pumps are essential components in many industries, including water treatment, manufacturing, agriculture, oil and gas, and residential systems. Because pumps often operate continuously under demanding conditions, selecting a pump with a long service life is critical for minimizing downtime, reducing maintenance costs, and ensuring operational efficiency. Choosing a long-life pump is not simply about buying the most expensive model—it requires understanding the application, materials, operating conditions, and maintenance requirements.

This article explores the key factors to consider when choosing pumps designed for long-term durability and performance.

Understanding Pump Lifespan:

A pump’s lifespan refers to the duration it can operate effectively before major repairs or replacement become necessary. Several factors influence longevity, including:

- Design quality

- Material selection

- Operating environment

- Maintenance practices

- Installation accuracy

- Load conditions

A well-chosen pump can operate reliably for many years, while an improperly selected one may fail prematurely even under moderate use.

Key Factors When Choosing Long-Life Pumps:

1. Proper Pump Type Selection:

Different pump types are designed for different applications. Selecting the wrong type significantly reduces lifespan.

Common pump types include:

- Centrifugal pumps — ideal for low-viscosity fluids and continuous operation

- Positive displacement pumps — suitable for high-viscosity fluids or precise flow control

- Submersible pumps — commonly used in wells, drainage, and wastewater systems

- Diaphragm pumps — effective for corrosive or abrasive fluids

Matching the pump type to the application is the first step toward long-term durability.

2. Material Selection and Construction Quality:

Material choice directly impacts resistance to corrosion, abrasion, and wear.

Important material considerations include:

- Stainless steel for corrosion resistance

- Cast iron for durability in general applications

- Bronze for marine or water-related environments

- Engineered plastics or composites for chemical resistance

- Ceramic or coated components for abrasive fluids

Higher-quality materials often cost more initially but provide longer operational life and lower maintenance costs.

3. Operating Conditions and Environment:

Pumps must be selected according to actual operating conditions rather than theoretical requirements.

Key parameters include:

- Flow rate and pressure requirements

- Temperature range

- Fluid characteristics (viscosity, abrasiveness, corrosiveness)

- Presence of solids or contaminants

- Ambient environmental conditions

Operating a pump outside its optimal performance range can cause overheating, cavitation, vibration, and premature failure.

4. Efficiency and Performance Curve Matching:

A pump should operate close to its Best Efficiency Point (BEP). Running far from this point increases:

- Mechanical stress

- Energy consumption

- Bearing and seal wear

- Vibration levels

Selecting a pump with performance curves aligned to the system requirements significantly improves lifespan.

5. Seal and Bearing Quality:

Mechanical seals and bearings are among the most common failure points in pumps.

Long-life pumps typically feature:

- High-quality mechanical seals

- Advanced bearing systems

- Proper lubrication mechanisms

- Seal protection systems for contaminated fluids

Investing in superior seal and bearing design reduces maintenance frequency and downtime.

6. Maintenance Requirements and Accessibility:

Even the best pumps require maintenance. A long-life pump should be:

- Easy to inspect

- Simple to disassemble and repair

- Supported by available spare parts

- Designed for predictive maintenance monitoring

Maintenance-friendly designs contribute greatly to extended service life.

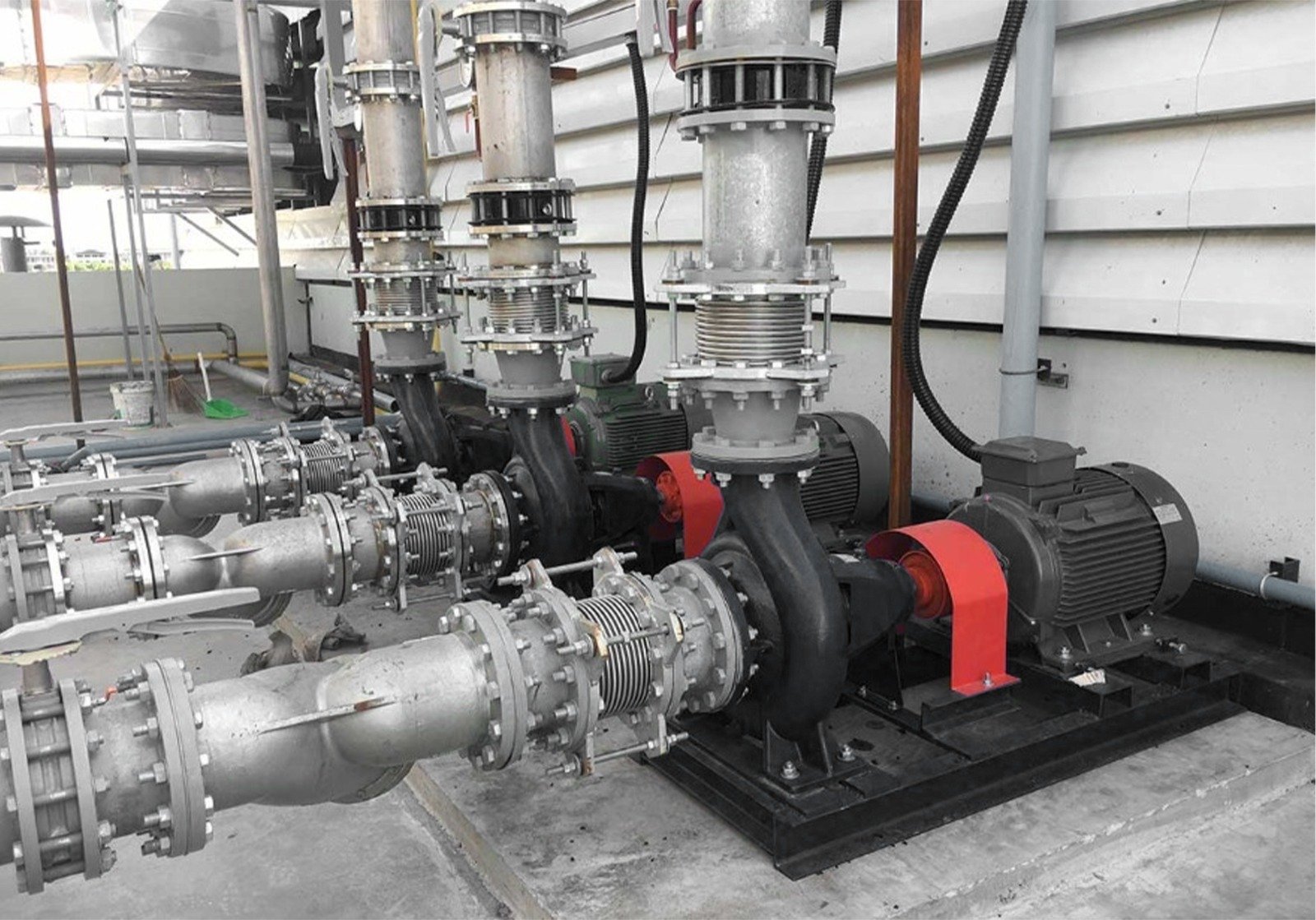

7. Installation and System Design:

Improper installation is a major cause of premature pump failure.

Common installation issues include:

- Misalignment between pump and motor

- Poor foundation or vibration control

- Incorrect pipe sizing

- Air entrainment or suction problems

- Inadequate cooling or ventilation

Professional installation ensures the pump operates under ideal mechanical conditions.

8. Life Cycle Cost (LCC) Considerations:

When choosing a long-life pump, initial purchase price should not be the only factor. Life Cycle Cost includes:

- Purchase cost

- Installation cost

- Energy consumption

- Maintenance and repair expenses

- Downtime losses

- Replacement cost

Often, a more expensive pump with higher efficiency and durability becomes more economical over time.

Technologies That Improve Pump Longevity:

Modern pump technologies can significantly extend service life:

- Predictive maintenance sensors

- Condition monitoring systems

- Wear-resistant coatings

- Smart control systems

- Variable frequency drives (VFDs) to reduce mechanical stress

- Advanced sealing technologies

These innovations help detect problems early and optimize operating conditions.

Common Mistakes to Avoid:

When selecting pumps, avoid these common errors:

- Choosing based only on price

- Ignoring operating conditions

- Oversizing or undersizing the pump

- Neglecting maintenance planning

- Poor installation practices

- Using incompatible materials with the fluid

Avoiding these mistakes dramatically improves reliability.

Benefits of Choosing Long-Life Pumps:

Investing in long-life pumps offers several advantages:

- Reduced downtime

- Lower maintenance costs

- Improved operational reliability

- Better energy efficiency

- Increased safety

- Higher return on investment

- Environmental sustainability through reduced waste

Long-life equipment supports both financial and operational goals.

Conclusion:

Choosing a long-life pump requires careful consideration of multiple factors, including pump type, material quality, operating conditions, efficiency, installation, and maintenance strategies. Rather than focusing solely on upfront cost, decision-makers should evaluate the total life cycle value and reliability of the equipment.

By selecting the right pump and maintaining it properly, organizations and individuals can achieve years of dependable performance, reduced operating costs, and improved system efficiency.